Level gauges are a type of level measurement devices that are mainly employed in the industrial instrumentation field to detect the level of fluids or liquid which is contained by a storage tank or process vessel. These levels product of sensing devices are considered very simple and fast to inspect the level fluids.

Select Your Level Gauges from Our Product Catalogue

1. Magnetic Level Gauge

2. Visual Level Indicator

3. Alternative Level Sensor

4. Level Switches

5. Point Level Detection

6. Potentiometric Level Switch

7. Magnetic Level Switch

8. Conductive Level Switch

Jogler Magnetostrictive Level Transmitter MGT-6000

Description :

Jogler’s MGT-6000 series liquid level transmitter is the latest development in magnetostrictive liquid level sensing technology that is designed exclusively

for magnetic level indicators. The MGT-6000 contains a low profile waveguide that is mounted away from the level gage chamber. This design isolates the waveguide from excessive vibration and temperature. From enhanced sensor technology, the output signal is very sensitive, fast, stable and accurate. The MGT-6000 can be mounted and retrofitted to most magnetic liquid level indicators.

Jogler Sight Flow Indicator

DIRECT-READING SITE FLOW INDICATORS

EXCLUSIVE, PATENTED FEATURES FOR MAXIMUM SAFETY AND ZERO MAINTENANCE Jogler Direct-Reading Flow Indicators are the simplest, most reliable way to observe liquid or solids flow without compromising the integrity of your piping system.

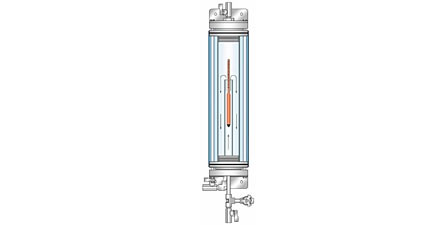

Jogler Direct-Reading Liquid-Level Gauges

Exclusive, patented features for maximum safety and zero maintenance

Superseal inserts for permanent, stress-free sealing

Simple, reliable, and maintenance-free

Jogler Magnetostrictive Level Transmitter

Bypass Chamber & Transmitter Combination

24 VDC nominal, two wire, loop powered

LCD display in 4-20 mA, in, cm, and/or percent

Selecting the Right Fluid Level Measurement Instrument

There are dozens of variations on the 22 technologies in the world of liquid

level measurement. Each one has a slight advantage in terms of some of the infinite combinations of range, tank shape, process materials, available power, pressure and temperature, and accuracy requirements. Our team of experts will assist you in narrowing the choices and focusing on the most appropriate technologies for your particular application. In selecting the level gauge, we should determine which factors are desirable and which are not. In practice, this is seldom carried out, and, frankly, there is a great tendency to reach for a differential pressure transmitter, if not a displacer, and live with whatever performance it produces. This is the cliché solution and, like so many clichés, it is, if not the wrong answer, often not the best. Petrotek’s engineering team works with you to find the best level measurement technology for your customized applications.

Types of Level Gauges

Petrotek is able to supply the following types of level gauges:

- Magnetic

- Magnetostrictive

- Laser Level Transmitter

- Direct-reading Indicators

- Frequency

- Hydrostatic

- Capacitive

- Ultrasonic

- Conductive

Magnetic Level Gauges

Because the magnetic level gauge does not require direct viewing of the level (i.e., there is no need for glass), the measuring chamber can be opaque, and welded metal construction is normally used. This substantially widens the operating temperature range and increases the ruggedness as compared to chambers using gauge glass. The wide temperature range is possible because the measuring chamber can have approximately the same coefficient of thermal expansion as the vessel, and there is no glass (which would have a lower t/c) to interface with the metal chamber.

Because the float in the chamber of a magnetic gauge incorporates a permanent magnet, any reliable method of detecting the location of a magnetic field can be used to show the location of the float and, thus, the level. Three common methods of indicating the float position are the magnetic follower, magnet-operated flags, and magnetostrictive linear position transducers (also called magnetostrictive transducers). Magnetically operated reed switches may require maintenance and lack the long-term reliability needed for many industrial applications. Therefore, we never recommend magnetically operated reed switches for Level Gauges.

Petrotek – Your Trusted Supplier of Level Gauges in Malaysia

Here at Petrotek, we provide products that are ideal for your level monitoring for both commercial and industrial tanking system. The level within these tanks can be checked and controlled by most of our level gauges and level sensors. We also offer a variety of indicators that will help you display the level of the tank.

We also offer a wide array of instruments for level measurement that varies according to the size and shape of a tank. Most of our level measurement tools are design for easy access and easy integration of the existing systems. Our designs are reliable and robust, offering the best solution that suits your needs and requirements.

Whatever you need, we have it here. Choose your ideal instruments and get in touch with us.